BWTS

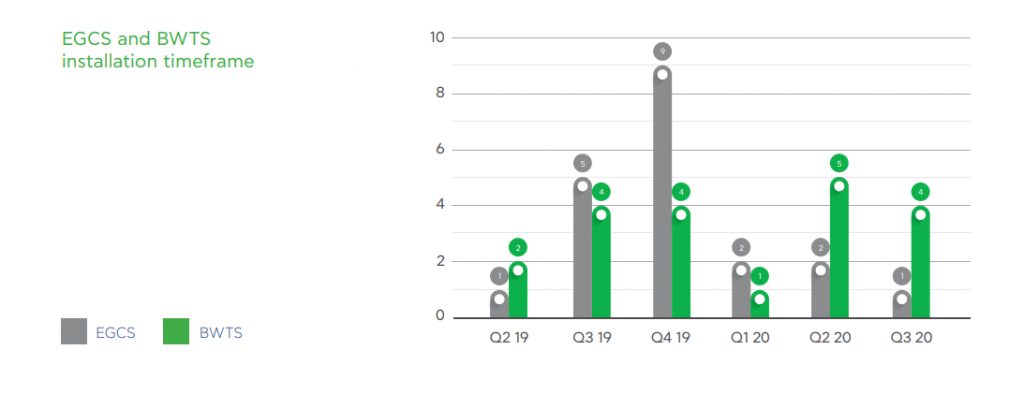

Installation of BWTS

When a ship is not laden, it uses ballast water to increase its draught and ensure complete propeller immersion. When ballast water is discharged back into the sea, invasive species may be unintentionally introduced to new habitats, destabilizing marine life. To counteract this IMO has enacted the Ballast Water Management Convention, which mandates that all vessels in international trade should manage their ballast water. Continuous ballast exchange is one way of temporary compliance with the regulations, but eventually, all ships need to install a system to treat their ballast water before releasing it back to the sea. Further to detailed evaluation, Safe Bulkers has decided the fleetwide installation of Erma First Ballast Water treatment systems. Erma First BWTS became the first full flow electrolysis system worldwide to receive the United States Coast Guard type approval certificate in October 2017. As of December 31st 2020, we have installed BWTS in 31 of our vessels, with very satisfactory results.

Scrubbers

Washwater Analysis Campaign

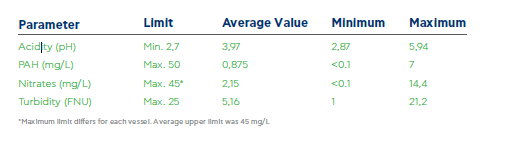

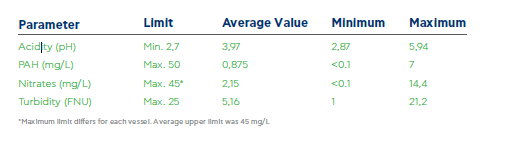

There has been much discussion regarding the quality of effluent water discharges by open-loop scrubbers. To alleviate these concerns, Safe Bulkers conducted a comprehensive sampling campaign to obtain data on washwater discharges from EGCSs, following the American Bureau of Shipping guidelines. The goal of this project was to assess any potential environmental impact of open-loop EGCSs and provide the IMO with the data obtained.

Water discharges from 19 of our vessels were sampled and analyzed between July 2019 and December 2020. Analyses were carried

out by independent laboratories, using EPA or ISO methods. The followingwashwater parameters were examined:

Acidity – pH

Polycyclic Aromatic hydrocarbons (PAH) (mg/L)

Turbidity (FNU)

Nitrates (mg/L)

Additives or other substances

Results are summarised in the table below:

As far as additives and other substances are concerned, inlet and discharge water was analyzed for a total of ten (10) dissolved metals.

Results showed very low or undetectable concentrations in both streams, inlet and wash water outlet. Increase of concentrations in wash water was either non-existent or marginal demonstrating that open loop scrubber wash water does not affect the marine environment. It should be noted that analysis and monitoring of such substances was performed for reference purposes only, on a voluntary basis, since no specific discharge limits have been established.

Scrubber operation below regulation limits

Moreover, we operate our EGCS well below ECA mode (0.1% Sulphur in the final emissions) at all times, even though the limit in most areas is 0.5%. In this way, our EGCS fitted vessels produce 8 times fewer sulfur emissions to the atmosphere compared to similar vessels burning compliant fuel.

MARPOL Proactive system

We have established a proactive system to prevent the violation of any environmental rule or regulation in our vessels. To this end:

We have installed CCTV cameras, monitoring certain engine room areas where such violations might take place

We have established a ship-specific tag-sealing system that is monitored by our on-shore personnel and inspected during ship visits.

Our engineers conduct environmental audits during ship visits.

Maintain a rigorous on-board environmental training program

Environmental impact of our on-shore activity

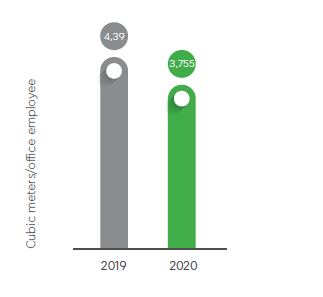

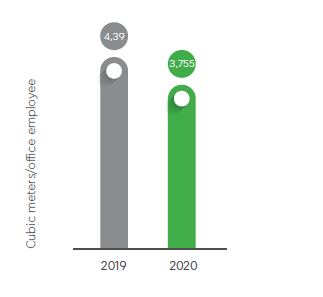

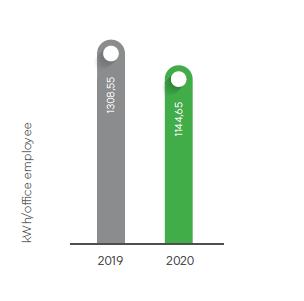

Our office water consumption per employee was reduced by 14.5% year to year, while our electricity consumption per employee was reduced by 12.5 % compared to 2019.

Office Fresh Water Consumption / Employee

Office Electricity Consumption/ Employee

Emissions Profile CO2 Emissions

We measure our operation’s transport energy efficiency and carbon intensity using the Annual Efficiency Ratio (AER, IMO DCS method). In

2020, we managed to reduce the AER of our fleet by 3.7 %. The reduction of AER is attributed to: i) increased transport work in 2020 by 3,2% compared to 2019 due to lower number of dry-dockings and related idle days and ii) reduced fuel consumption in 2020 by 5% compared to 2019 due to improved hull efficiency because of the dry-dockings.

- Web Design & Development by Generation Y